Press Brake Tooling

Manrepco has been supplying customers in South Africa and worldwide with standard and customised tooling for a wide range of sheet metal and plate applications for over 30 years.

Services

-

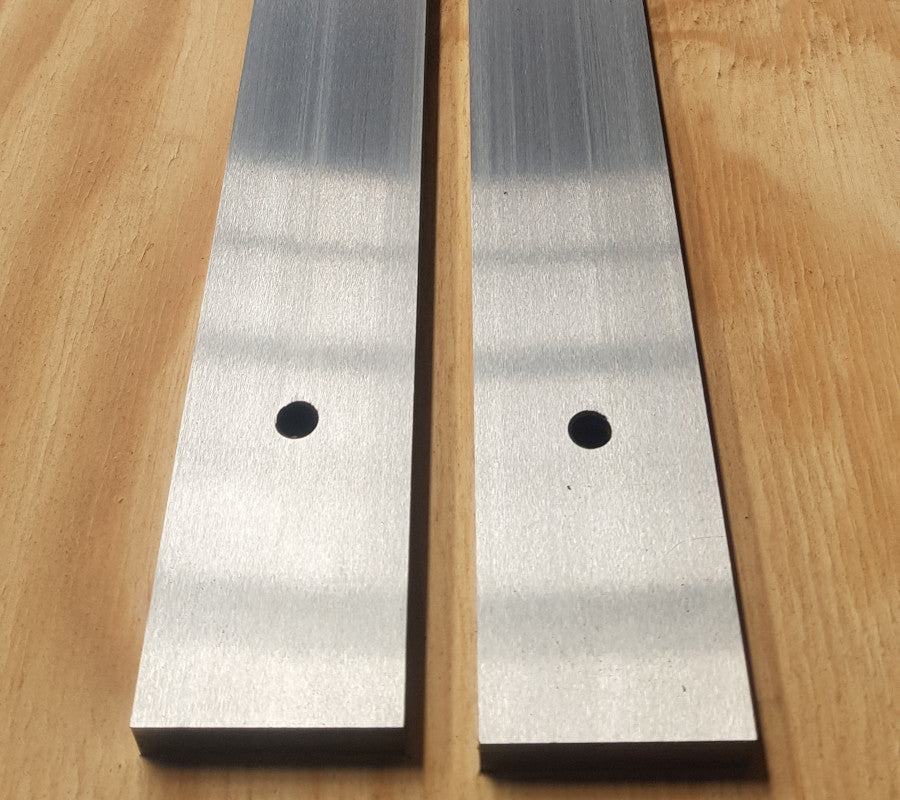

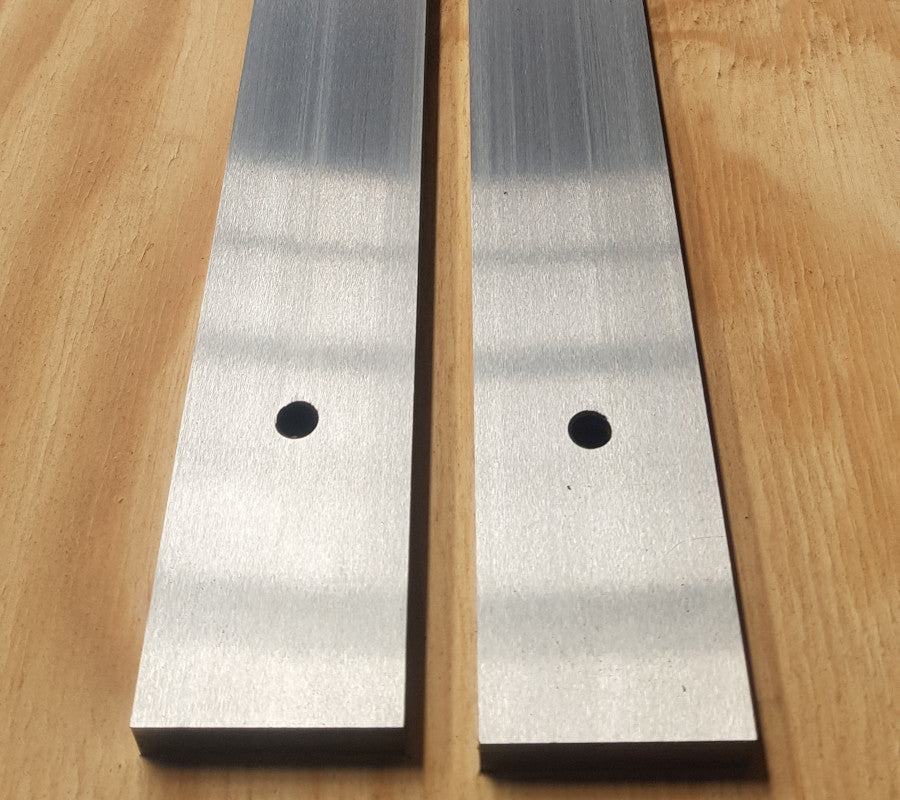

Guillotine Blades

Our made to order guillotine blades can be designed for your specific use case. We can customise material selection, hardening and post treatment of our blades to find the right balance of cost, delivery, and lifespan to match each of our customer’s unique requirements.

-

Press brake tooling

Manrepco has been supplying standard press brake tooling for over 30 years. We can provide replacement tooling for every machine tool that will match existing tooling and last as long, or longer than the original OEM tools.

-

Tool reconditioning

Manrepco can recondition your existing damaged and worn tooling. We also offer a service to rebuild and weld localized damage before regrinding, minimizing the tooling lifespan lost during grinding and sharpening.

-

Custom tooling

Manrepco designed custom tooling unlocks the potential of your bending machines. By using custom-designed tooling, your bending machine can make multiple bends in a single stroke, create a scratch free finishes on problematic materials, and even reduce the bending force, multiplying the power of existing machinery.

Case Studies

-

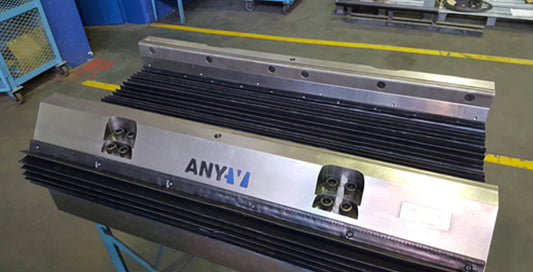

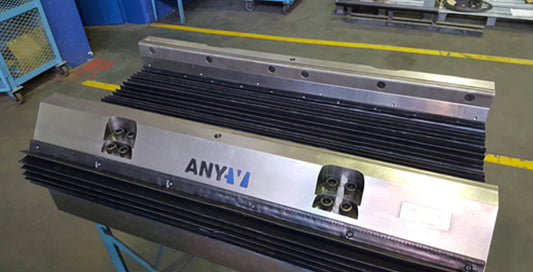

Testing the Any-V at Bell Equipment

Bell equipment had a workflow that consisted of two shifts of plate bending operations, followed by a third shift changing the tooling and setting up the machine for the next...

Testing the Any-V at Bell Equipment

Bell equipment had a workflow that consisted of two shifts of plate bending operations, followed by a third shift changing the tooling and setting up the machine for the next...

-

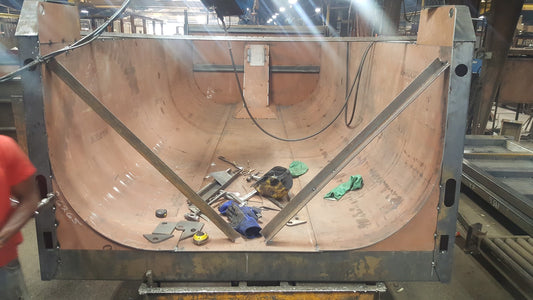

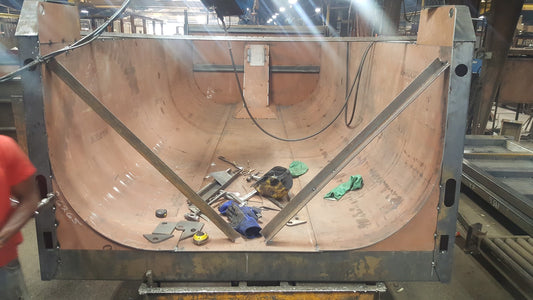

Case Study - Warren, Inc

The client makes load bodies in 6mm Hardox 450 and each side needed ten bends. Added to the high production cost with over four hours machine time, the accumulated errors...

Case Study - Warren, Inc

The client makes load bodies in 6mm Hardox 450 and each side needed ten bends. Added to the high production cost with over four hours machine time, the accumulated errors...

-

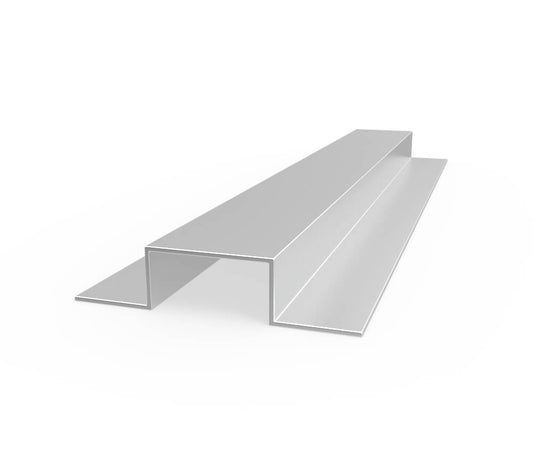

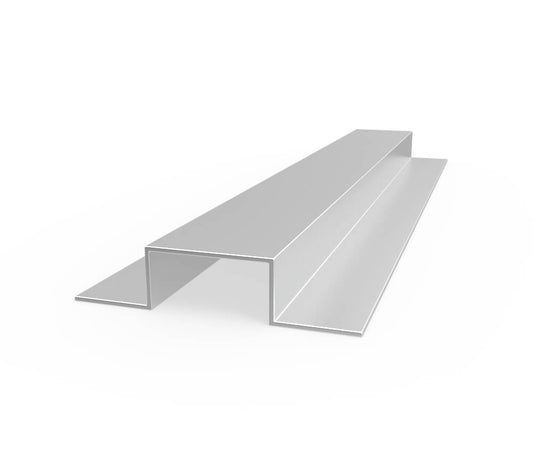

Case Study - ShelvCraft cc

Shelvcraft used U-shaped channels as reinforcing on their shelving products. The channels were being bent in 4 strokes, out of 1mm thick material, and this was identified as a bottleneck...

Case Study - ShelvCraft cc

Shelvcraft used U-shaped channels as reinforcing on their shelving products. The channels were being bent in 4 strokes, out of 1mm thick material, and this was identified as a bottleneck...